Each of our technicians is experienced in evaluating and preparing the concrete floor to meet our rigorous standards. The first step is the most critical; we prepare the surface with the use of one or more diamond grinders. This process is paramount to achieving a porous and contaminant-free surface. The process is continued by performing any crack/divot repair and caulking the entire perimeter, if necessary. The expansion joints (if present) are partially filled with an elastomeric sealer.

After the appropriate preparation of the substrate, this coating system involves the application of three layers: one epoxy base coat, a full layer of polyvinyl acetate (PVA) color chips and one clear top coat. Day one involves the application of a single epoxy color coat followed by the application of a full layer of the PVA color chips into the base epoxy coat. Day two involves the application of one high solids clear top coat.

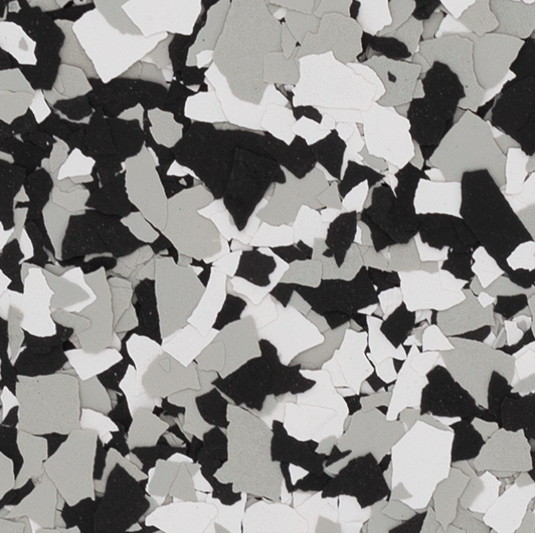

Domino

FB-411

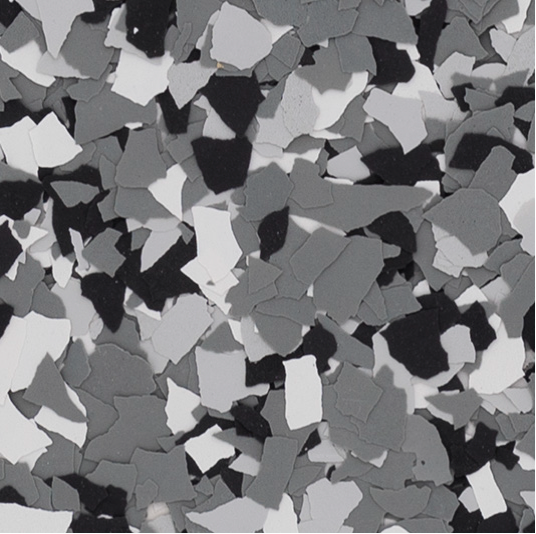

Wombat

FB-616

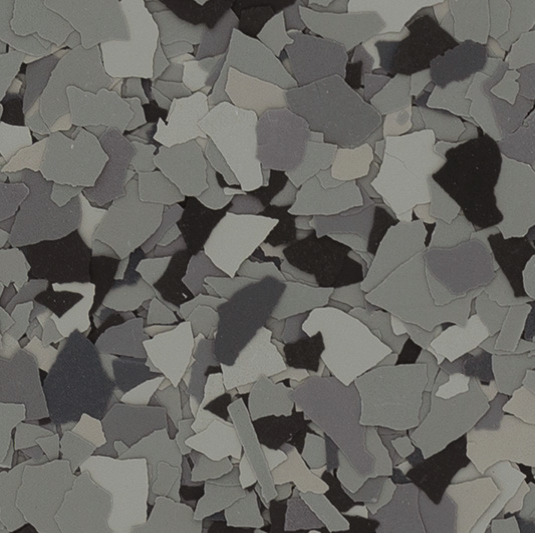

Nightfall

FB-715

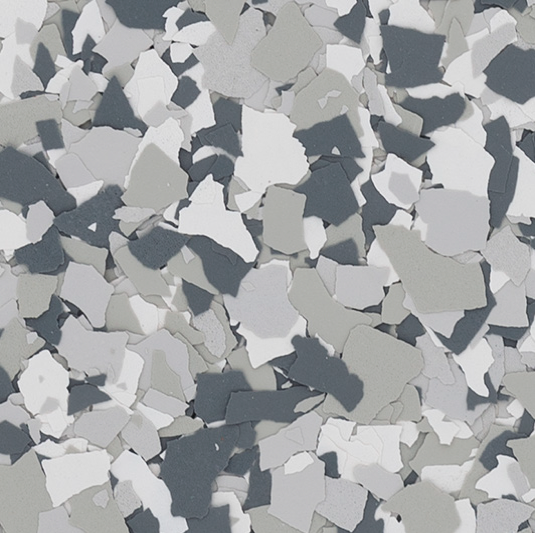

Gravel

FB-414

Orbit

FB-310

Tidal Wave

FB-807

Creekbed

FB-716

Cabin Fever

FB-127

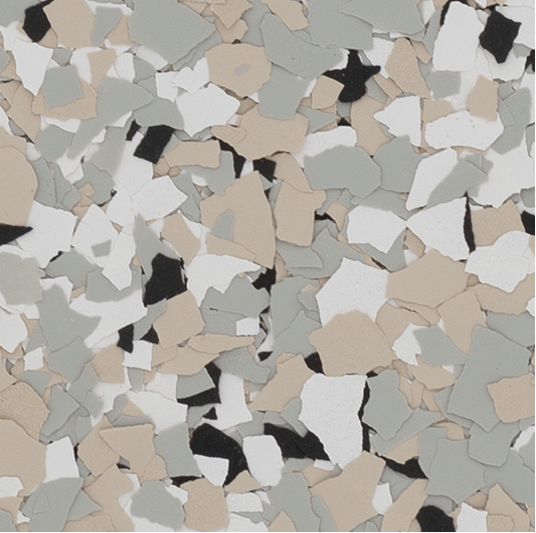

Shoreline

FB-421

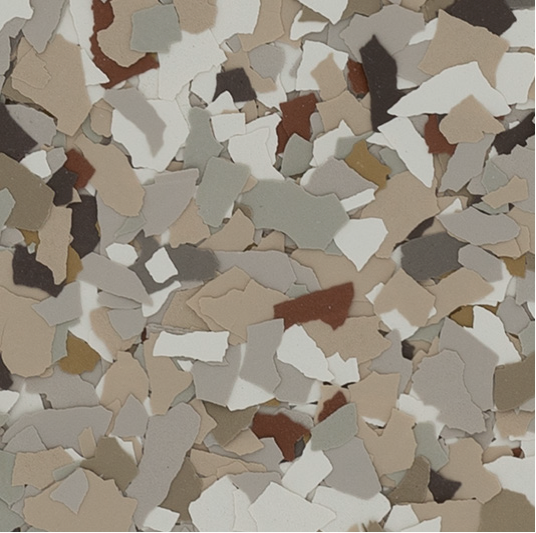

Outback

FB-517